When looking at whole herd profitability, a producer’s focus tends to be directed towards the cows — the animals who are making money today. However, according to Dr. Kelly Reed, a veterinarian with Diamond V, dairy producers have an opportunity to do a better job of raising heifers by incorporating basic technology that can help them to improve their heifer programs and animal lifetime performance.

David Mathes, director of sales and marketing for DBC Ag Products, a company that specializes in the development and marketing of innovative biotechnology in animal health, concurs with Reed. He emphasizes that what drives producers to implement technology should be geared more towards the health and nutritional benefits to the calf rather than just on labor savings.

“Producers will reduce labor and [create] efficiencies, but management time will increase,” Mathes says. “A good manager is critical; if a system goes down — not cleaning or mixing properly — the growth curve and health of a calf can change quickly.”

Shawn Miller with Pagel’s Ponderosa in Kewaunee, Wis., has been utilizing technology with his calf manager role for several years.

“Technology makes you think differently and teaches you to approach situations differently,” he adds. “A once difficult task now is simple as just a few keystrokes.”

While the milk check might not entice big-ticket spending, more affordable technology, including data analysis programs, calf scales and pasteurizers, are being utilized in raising calves and heifers.

Data analysis programs

With data analysis programs, Reed suggests utilizing programs that look at calf health records, using real time data and making it usable to producers. While technology allows for a better job of collecting data, she reiterates that management is still required to analyze the data, as well as the need to visually look at the calves. “This is where technology for youngstock comes into play,” she says. “Health data is vital in making timely decisions on determining both culling and rearing decisions to have the best animals for the future.”

Along with an RFID wand, Pagel’s uses DairyComp’s app-based program, which allows them to simultaneously collect data and input it into the computer straight from a handheld device. Multiple lists are generated from DairyComp that allow the Pagel’s team to efficiently vaccinate young stock.

“What we can do with DairyComp is a game-changer,” Miller says. “If you know what to tell it, then it will generate the lists and reports.”

Calf Scales

As the cost of raising heifers has skyrocketed, the dynamics of raising heifers has changed. Reed states that more of her clients are purchasing scales and putting them to use to weigh calves.

The saying, ‘You can’t manage it, if you can’t measure it’, is true Reed says.

For years, Pagel’s has been individually weighing calves on a digital scale that reads RFID tags at birth, again at weaning and finally between four and five months of age. The weight data automatically uploads into DairyComp and Miller receives the average daily gain weights to know how calves are performing. His management decisions, like culling and increasing the milk volume fed, are made based off that data. Technology helps Pagel’s make the most of their culling decisions before the calf hits six months of age.

Pasteurizers

Calf pasteurizers are becoming more common as dairies look to reduce costs and improve consistency. Most dairies that Reed works with are feeding waste milk to calves and have invested in a pasteurizer. Mathes says that pasteurizers work, but they must be properly managed. One of the biggest issues he sees when troubleshooting problems on dairies is from a lack of cleanliness.

Reed notes that many dairies are also using a pasteurizer for colostrum, and she recommends an inexpensive colostrometer to help evaluate colostrum quality.

“Or if you want a more precise reading of the total solids use a Brix refractometer, which is easy to use,” she adds.

Mathes agrees with checking the quality of colostrum, but also recommends using your sight and smell to help assess its quality. The pair also recommend running a pre- and post-pasteurizer test through a milk lab to make sure pasteurized milk is being heated correctly.

Facts versus myths

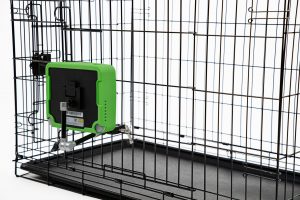

With more expensive purchases, like robotic calf-feeding systems, Mathes says that robotic calf feeders do not necessarily reduce labor. Instead, this technology requires higher-skilled labor. He notes that these kinds of systems are good on their own, but can work wonders when paired with data and observational management.

“You have to closely watch the calves; they will ‘talk’ to you and they will tell you how they’re doing,” Mathes says.

One of the biggest challenges with implementing technology is that calf management must change, and everyone has to be on board. Health can become an issue if feed rates are off or sanitation is not performed properly. Mathes also notes that diseases can transfer quickly from calf to calf in a group-housing setting and recommends keeping a close eye on calves.

“Both maintenance and management are required with technology,” Mathew adds “By the time you notice system failure or breakdown, it can be too late.”

The evolution to technology and housing calves is coming fast to dairies. Miller suggests centering in on the data that technology offers and utilize a strong management system. Doing so allows you to marry together your calf and heifer program and form a brighter future for your operation. However, even when using technology, Miller still sees the value in walking the rows of calves daily.

“The human eye can see things that computer can’t,” he says.

Lire la suite: www.dairyherd.com